1. Company introduction

Unique Transmission Equipment (Luoyang) Co., Ltd. is an innovative technology company that designs, develops and produces slew drives and slewing rings. We have a wide range of standard series products to choose from, we also focus on customized slew drive and slewing ring solutions.

We have created 3D models for all standard models of slew drive products. You only need to put 3D model in your equipment model to verify the feasibility. If the standard slew drive products are not available, our engineers with rich industry experience can design a new 3D model and work with you to design an ideal slewing transmission solution.

Below are the photos of our production equipment.

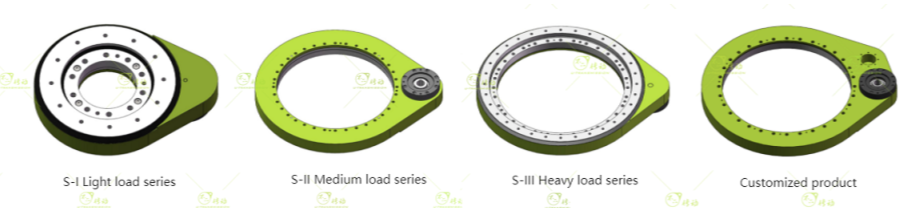

2. Spur Gear Slew Drive Introduction

Spur gear slewing drive is composed of slewing bearings, gears, housings, adapter flanges, support bearings, seals and other components. After reasonable design, component manufacturing, debugging, assembly and other processes, the products have the ability to withstand axial force, radial force, tilting moment torque and at the same time has a certain gear ratio, referred to as slewing drive.

Our spur gear slew drives has 3 series, 23 standard models in total to choose from, which can meet the needs of low load, medium load and heavy load. If our standard model products cannot meet your needs, you can also contact us and our engineers will design and customize a special spur gear slew drive for you.

3. Dimension Details

(You can also download our catalogue to check more code details)

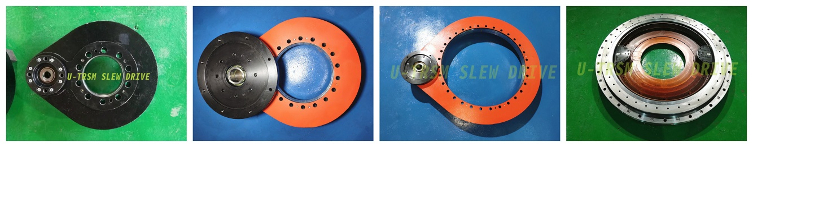

Code: SP-I-0260

Type: External gear precision spur gear slewing drive

Gear ratio: 6.4

Rated output torque: 2800N.M

Rotation center diameter: 260mm

Total height with adapter flange: 90mm

Gear backlash: ≤0.1mm

SP-I-0260 external gear precision spur gear slewing drive is used in industrial automation equipment. The customer installs the planetary reducer and the servo motor for indexing, requires a precision slewing drive, requires the gear backlash ≤0.1mm, according to customer needs, we designed a precision SP-I-0260 external gear slewing drive for customers, the slewing bearing still adopts small clearance and high rotation accuracy to ensure that the slewing bearing can achieve very small tooth runout after grinding gears, cooperate with grinding pinion gears and experienced and skilled masters for assembling and debugging, such a combination will definitely make an ideal product.

Through continuous accumulation, Unique Transmission is becoming more and more good at making high-precision slewing drives. We continue to summarize and accumulate, constantly try to analyze, continue to improve and optimize the design, provide customers with reasonable solutions. We have reasonable processes for parts production to ensure that we can make parts that meet the requirements. We have an experienced team in the assembly, debugging and testing process. When you need a slewing solution, please contact us.

4. Packing Way

1) Apply anti-rust oil on slewing drives.

2) Using wrapping belts to package the slewing drive.

3) Place the packaged slewing drives to the plywood cases.

4) Using pearl cotton to fix the slewing drives in the boxes and confirm the products will not move during transportation.

5) Using packing belts to pack the wooden cases.

6) Stick the shipping marks to let our customers identify goods easily.

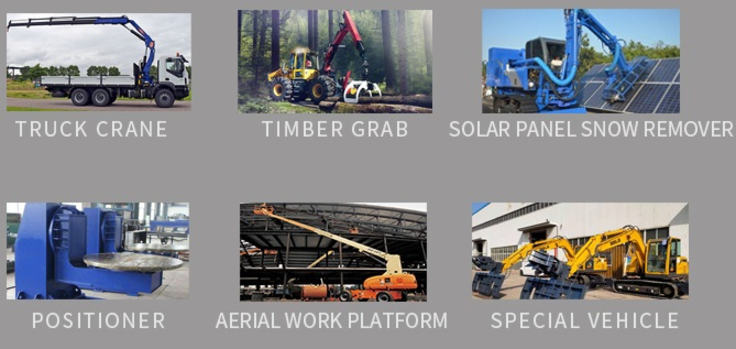

5. Application Area

Spur gear slew drives applications mainly include industrial robots, machine tool turrets, cranes, truck-mounted cranes, automated production lines, light machines, radar cars, positioners, flexible bending machines, grass grabs, solar panel snowplows, forestry machinery, agricultural machinery and other fields. You can also check our mounting videos to learn how to use it.

6. Transportation: By sea/ air/ rail/ road/ TNT/DHL/UPS/Fedex, all acceptable.

7. Contact information

Unique Transmission Equipment (Luoyang) Co.,Ltd

Address: No.22 Binhe Road, New & High Tech Industry Development Zone,

Luoyang Area Of China(Henan) Pilot Free Trade Zone, 471000